Zero Dead Volume (6cm, V6 Syringe) Syringe Designed for Customer's Instruments

The 6cm V6 syringe is designed and manufactured under stringent manufacturing and quality standards.

SPECIFICATION AND QUALITY

The required quality of a syringe depends on the application and conditions of use. We have to take these conditions into consideration. At the design stage to produce the most suitable syringe.

- Kind of solution used

- Cycle of piston movement of plunger

- Operating temperature

- Power of motor for plunger action

- Method of fitting to the equipment

- Tolerance of dimensions

ACCURACY

The annealed 3.3 borosilicate glass barrel maintains stable and enduring sampling. High uniformity of barrel dimension and mirror finished surface provide an accuracy and reproducibility within ±1%.

MANUFACTURING

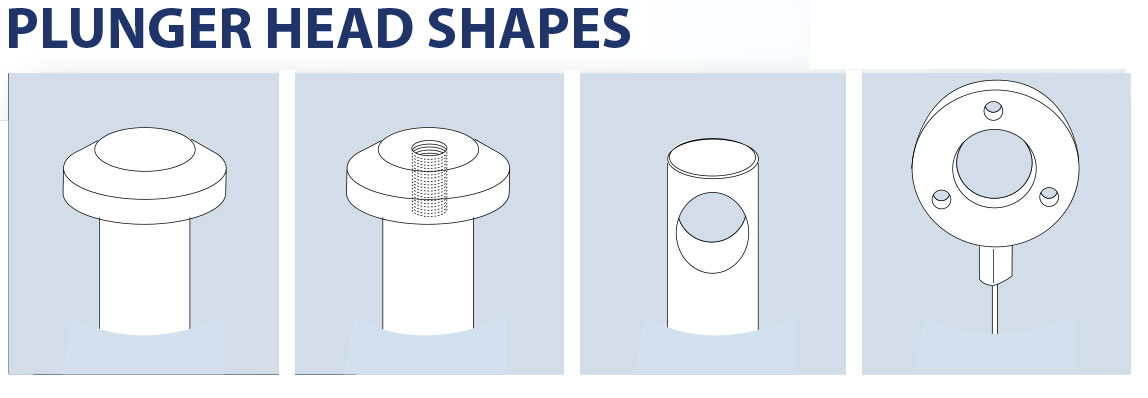

Precision manufacture of each part (holder, glass barrel and plunger) ensures a smooth plunger action, accurate sampling and extended plunger PTFE tip life. Our superior processing techniques in glass, metal and plastics can meet any original specifications. A wide variety of materials are available for different applica- tions.

- Stainless steel: SUS303, 304 and 316 etc.

- Plastic: PTFE, PCTFE, UHMW

Physical

- Length: 4.37"

- End Cap: ¼-28 Plunger Button: XL style Optimal Internal Pressure 80 PSI

Environmental

- Storage Temperature: 10°F to 180°F °C

- Operating Temperature: 50°F to 104°F

- Humidity: up to 100%

Chemical

- Wetted Materials: Borosilicate Glass, Kel-F (CTFE), Teflon (PTFE), UHMW (optional tip material), Lubricated with Medical grade lubricant

Performance

- Cycle life: PTFE Tip= up to 400K full stroke cycles* UHMW Tip = up to 800k full stroke cycles* Accuracy/Precision 1% at 10% of total volume (with Di Water)

ZERO DEAD VOLUME SYRINGE

are used ind various Field requiring

PRECISION INJECTION

- Chromatography

- Biochemical Filed

- Medical Inspection

- Industrial Instruments

For Parallel Samples Withdrawal & Doasge in MultiSyringe Pumps

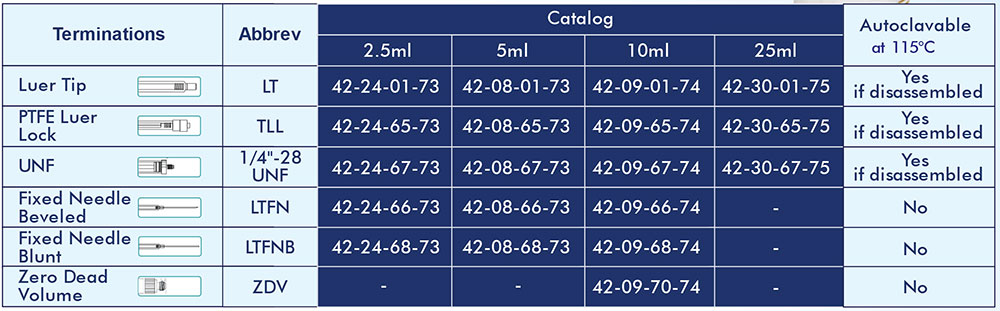

Gas Tight Syringes

Gas Tight syringes are ideal for dispensing both liquids and gases.They have a precision-machined PTFE plunger tip which creates a leak-free seal.With the tight fit, the tip essentially wipes the interior of the syringe barrel free of sample.This feature is particularly useful with heterogeneous samples as it reduces the chance that a deposit will occur and cause the plunger to freeze.

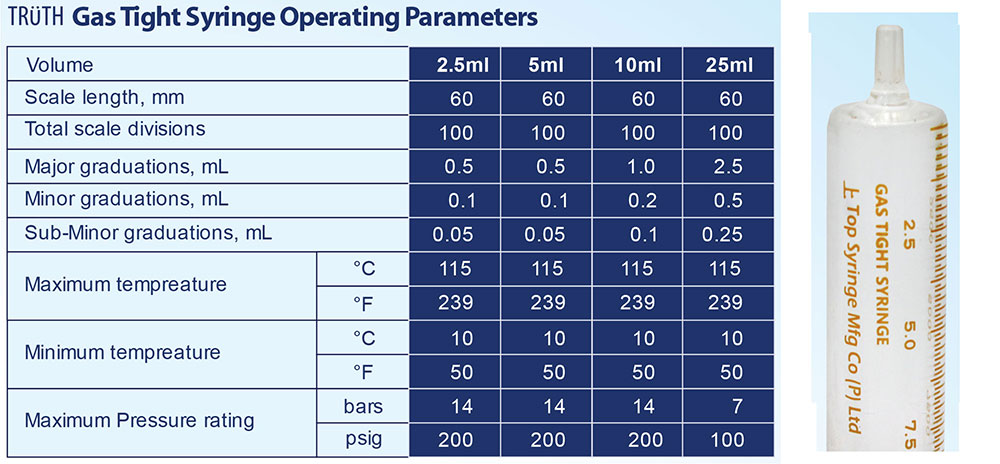

Gas Tight Syringe Operating Parameters

Gas Tight Syringes

Gas Tight syringes are ideal for dispensing both liquids and gases.They have a precision-machined PTFE plunger tip which creates a leak-free seal.With the tight fit, the tip essentially wipes the interior of the syringe barrel free of sample.This feature is particularly useful with heterogeneous samples as it reduces the chance that a deposit will occur and cause the plunger to freeze.

Top Syring Compound, Western Express Highway, Behind Samarat Hotel,

Next to Aqua Lodha, Pandurang wadi, Mira Rd (E), Thane 401 104, Mumbai, INDIA

Mobile No: +91 9769175036

Email: sales@top-syringe.com,

website : www.top-syringe.com

Alovie Technologies

Plot#609, 1st floor, Pragathi Nagar,

Opp. to JNTUC, Kukatpally,

Hyderabad, Telangana.

Email: info@alovie.com

Website: http://www.alovie.com/