HPLC / Autosampler Vials

ND 8 Screw Neck Vials 12 x 32mm

Why Select 8mm Screw Neck Vials?

8mm (8-425) screw neck vials are the original smaller opening autosampler vials manufacture with USP type 1 glass. They are designed to work in a variety of autosamplers requiring narrow neck vials.

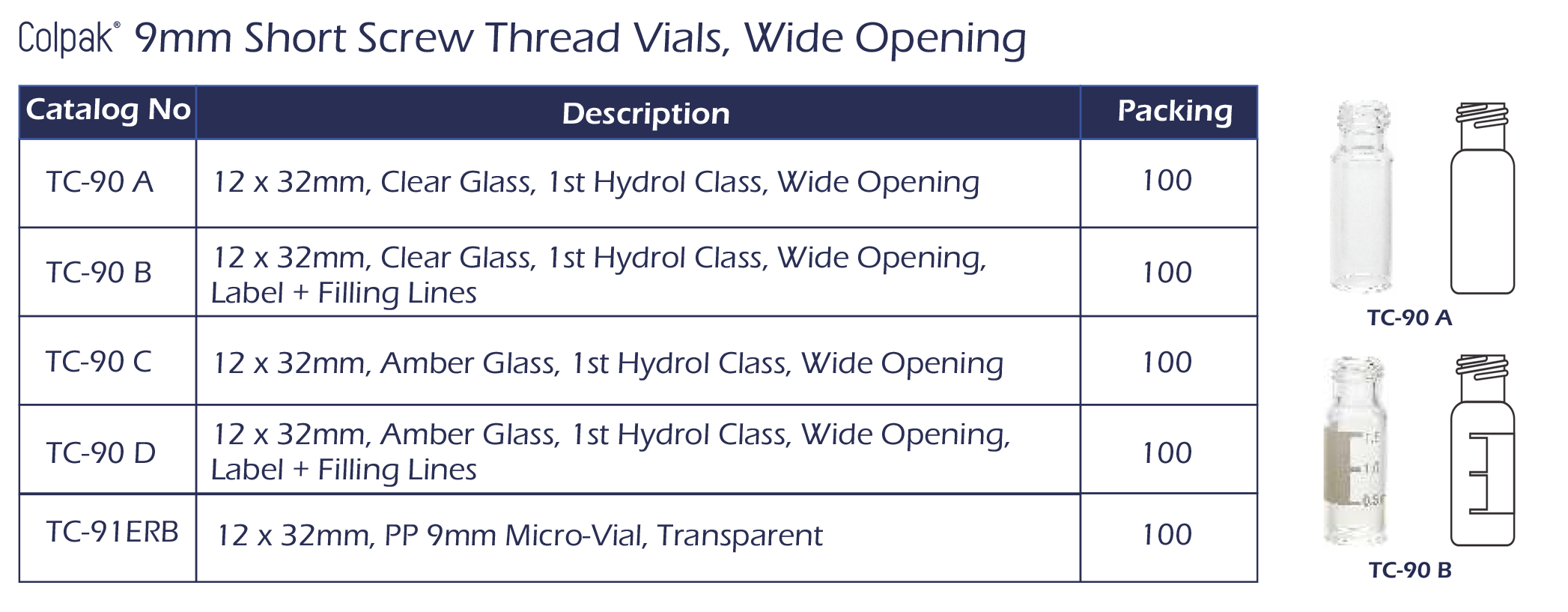

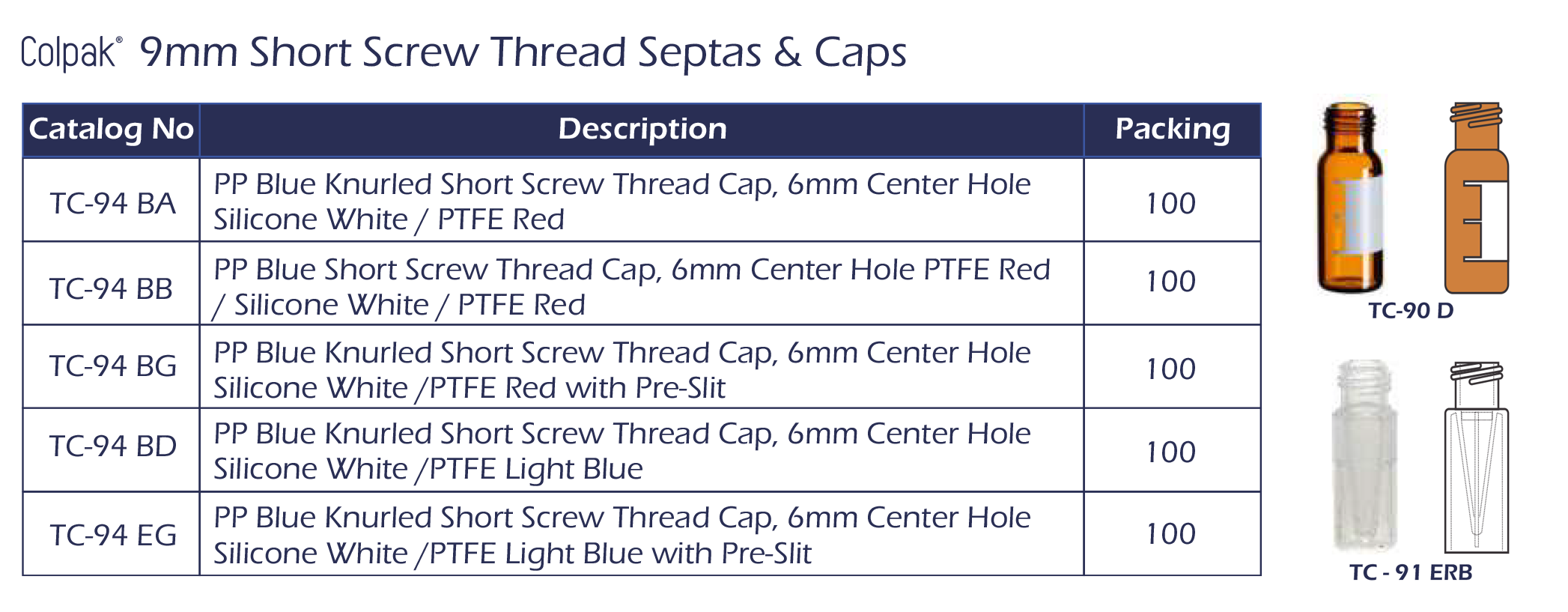

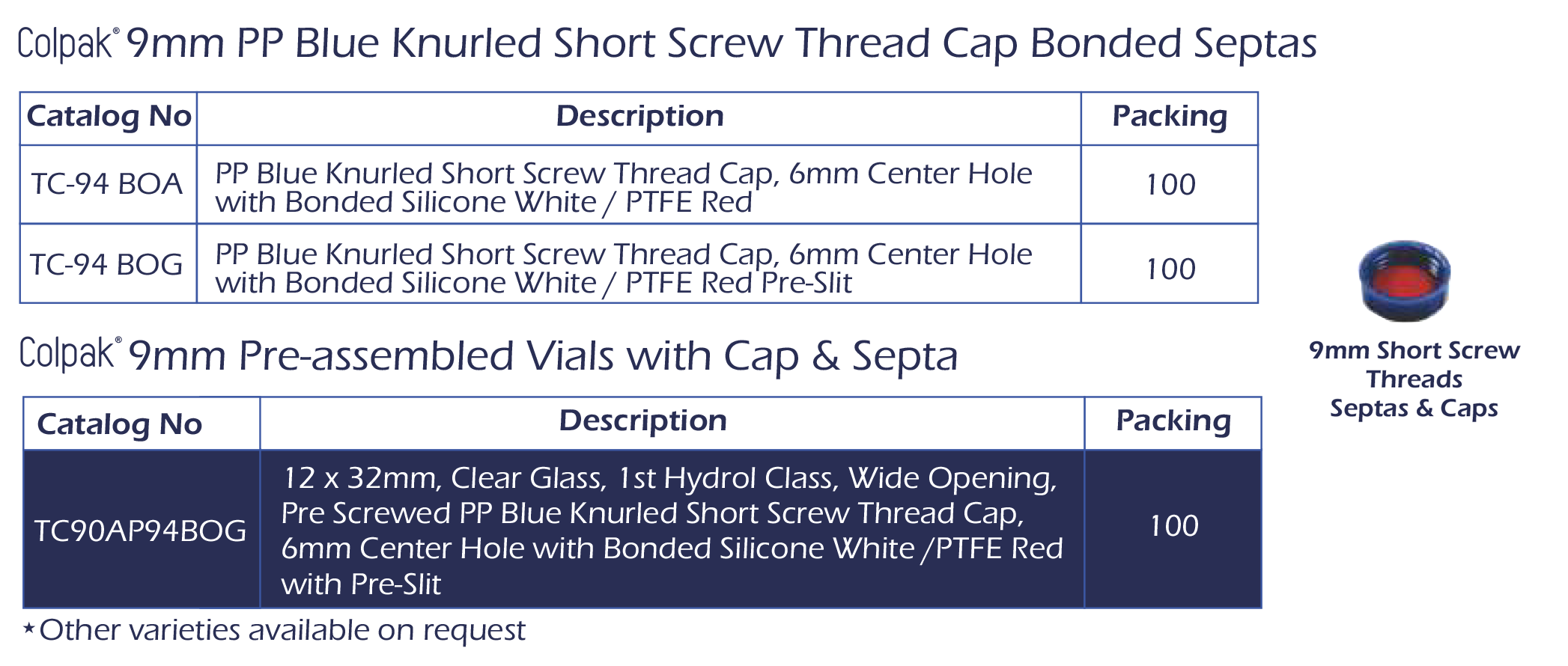

ND9 Short Screw Thread Vials 12 x 32mm

Why Select 9mm Short Screw Thread Vials?

9mm screw thread vials have a 9-425 GPI thread and the closure is dimensionally equivalent to 11mm crimp cap vials.This means that they can be used in any autosampler that uses 11mm crimp cap vials. 9mm screw caps have an advantage over 11mm crimp caps because 9mm screw caps can easily be applied and removed by hand and they can be reused. All vials are manufacture with USP type 1 glass.

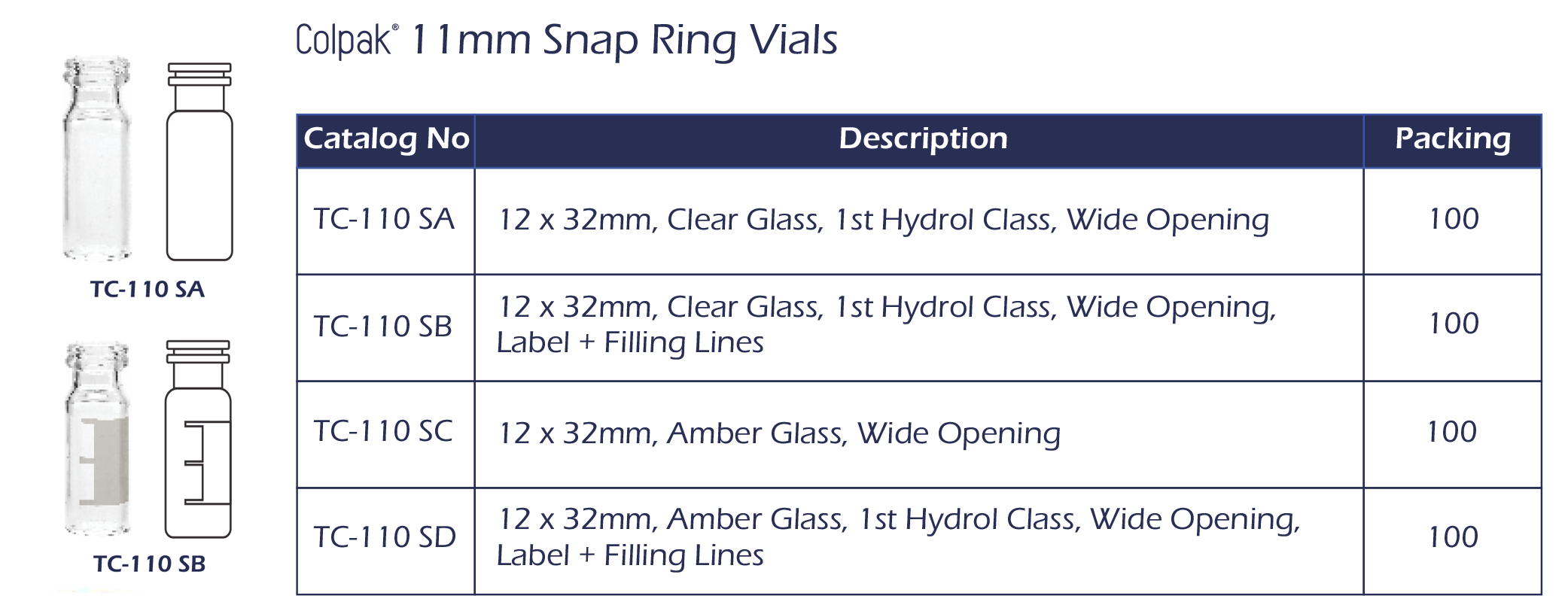

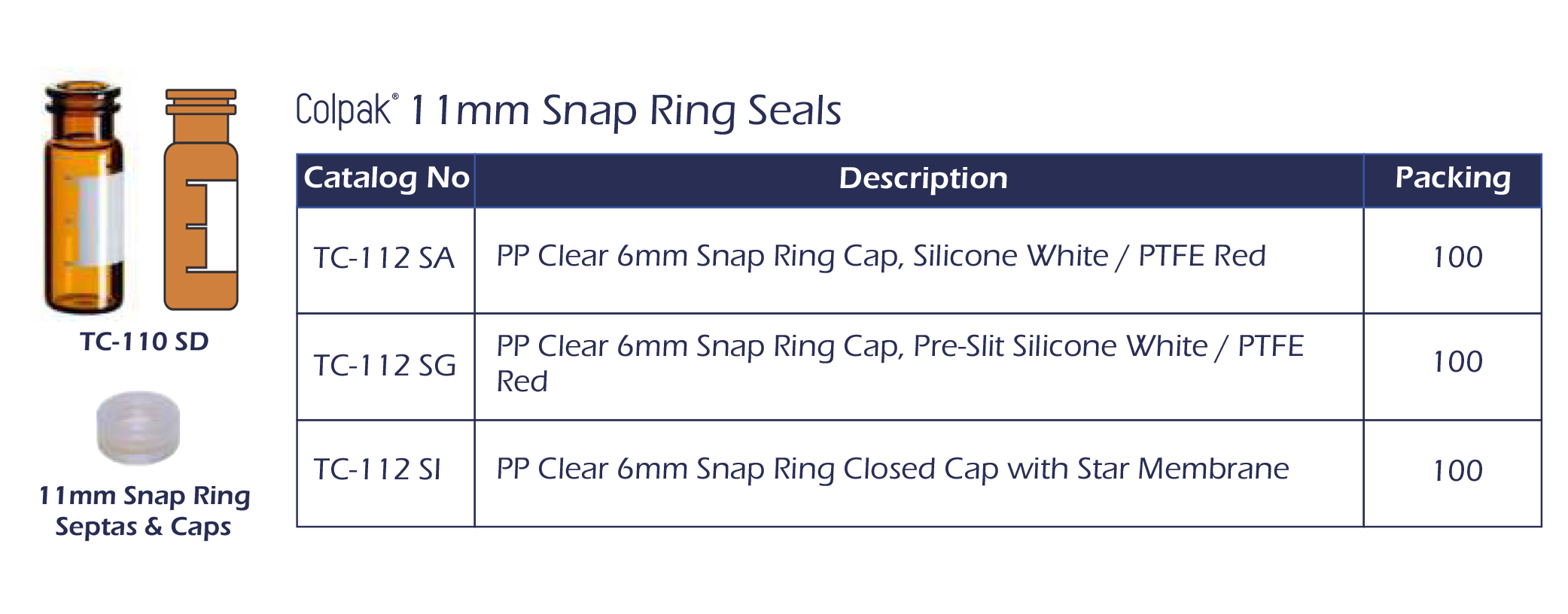

ND 11 Snap Ring Vials 12 x 32mm

Why Select 11mm Snap Ring Vials?

11mm snap caps provide a secure seal that minimises evaporation, even with volatile samples. Snap caps are often more convenient than crimp caps as they can easily be applied and removed by hand. An audible click ensures a secure seal has been formed and that the cap is correctly aligned. Snap/crimp vials can be closed with either snap caps or crimp caps. All vials are manufacture with USP type 1 glass.

ND11 Crimp Neck Vials 12 x 32mm

Why Select 11mm Crimp Neck Vials?

Crimp caps provide the tightest seal, reducing the chance of sample evaporation. The 12x32mm crimp vials and 11mm aluminium crimp caps are economical and easy to use with crimping tools. All vials are manufacture with USP type 1 glass.

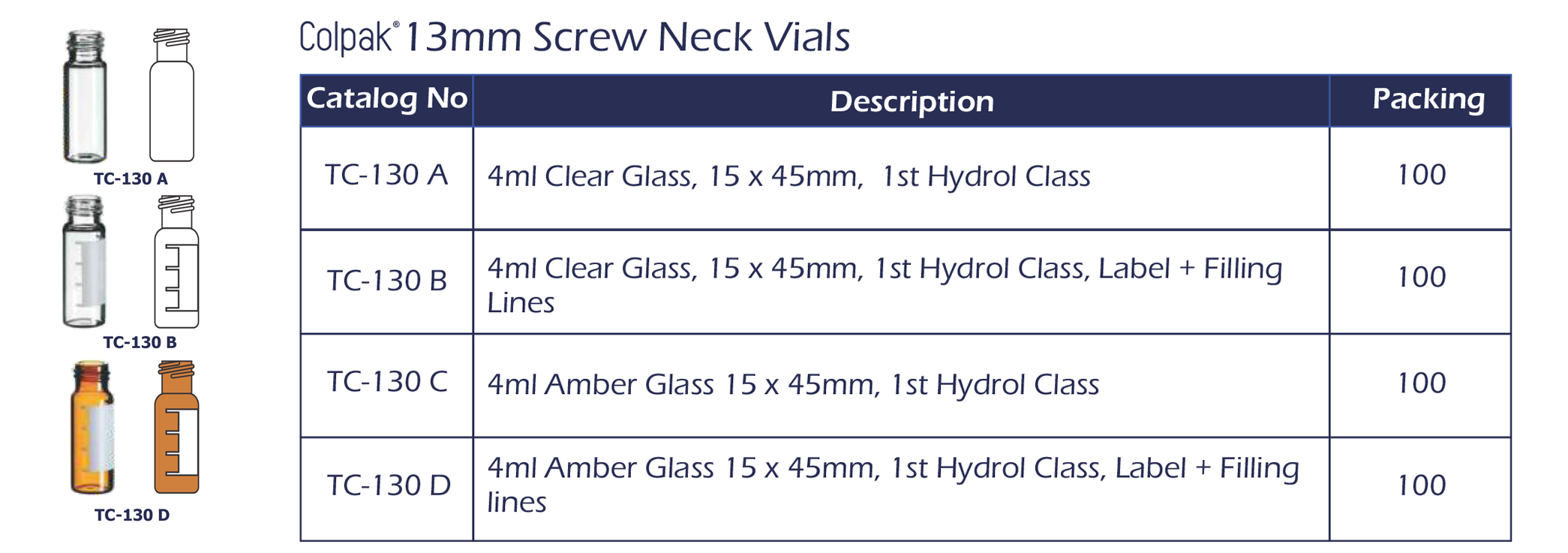

ND 13 Screw Neck Vials 15 x 45mm

Why Select 13mm Screw Neck Vials?

13mm vials have a 13-425 GPI thread and can hold up to 4ml of sample. They are used by the Waters 48-position autosampler and many others. All vials are manufacture with USP type 1 glass.

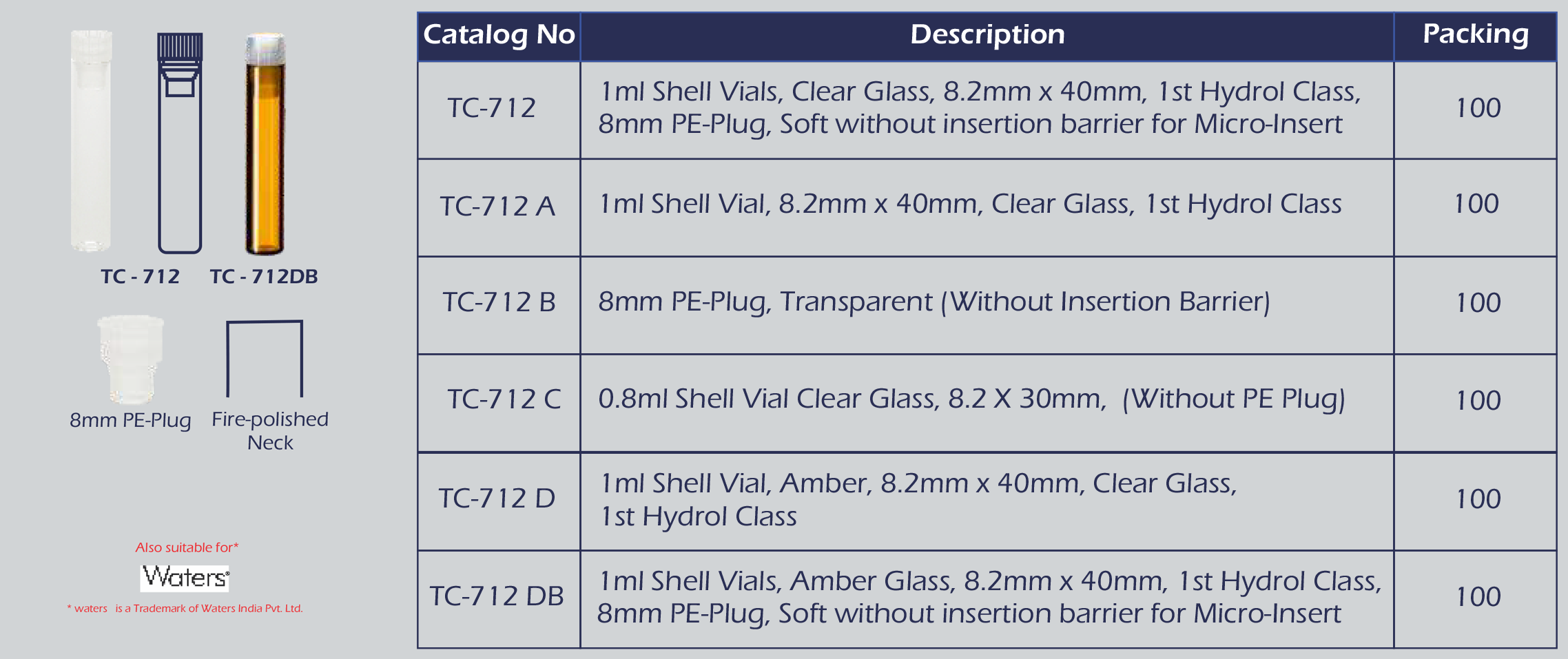

Shell Vials

Why Select Shell Vials?

Shell vials feature thicker walls for safer sample handling. They are compatible with Waters WISP™ 48 and 96 style autosamplers. All shell vials are supplied with polyethylene plug closures – their tear-away design ensures excellent penetration and ventilation during sampling.

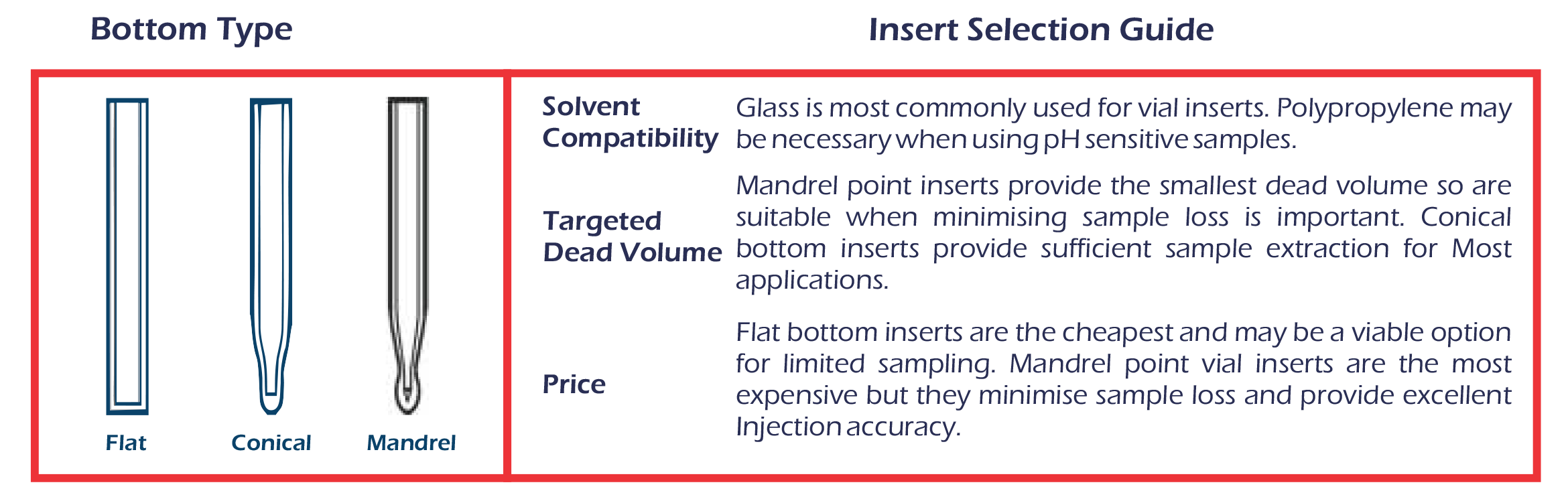

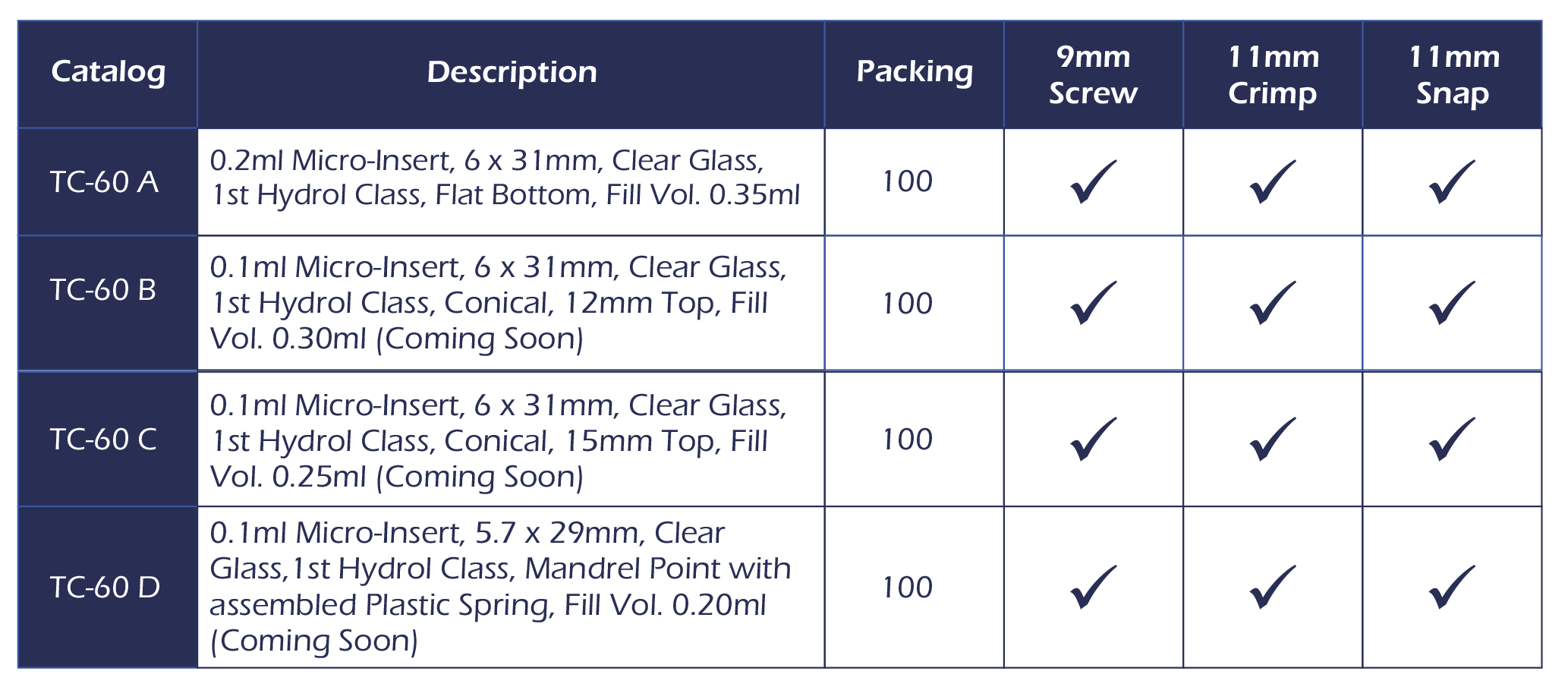

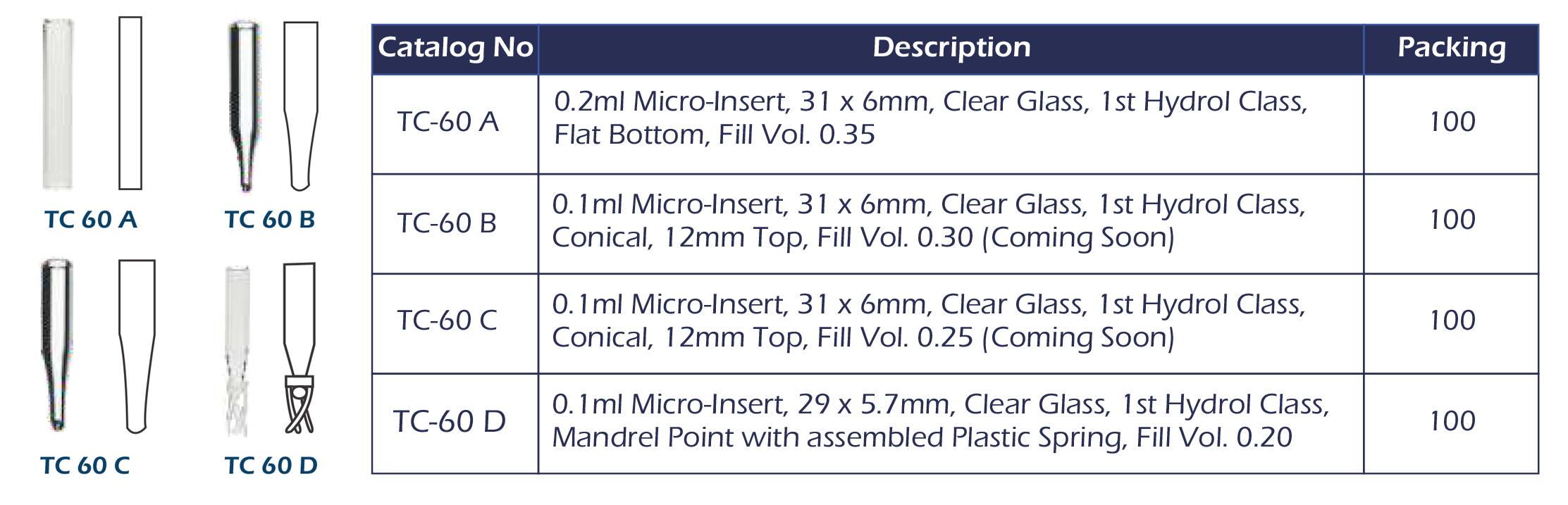

Limited Volume Inserts

Why Select Limited volume Inserts?

Limited volume inserts are an economical solution in sample analysis to reduce the use and waste of solvents and small samples. For optimum instrument performance and accurate test results, use the guides below to ensure that the correct insert is used with the appropriate autosampler vial. The Insert is neckless and always has to be used within a vial. The diameter of the Insert depends on the size of the vial opening. Inserts reduces the volume, so that the needle is capable of picking up even smallest sample quantities. The larger the top of an insert, the more the volume can be reduce.

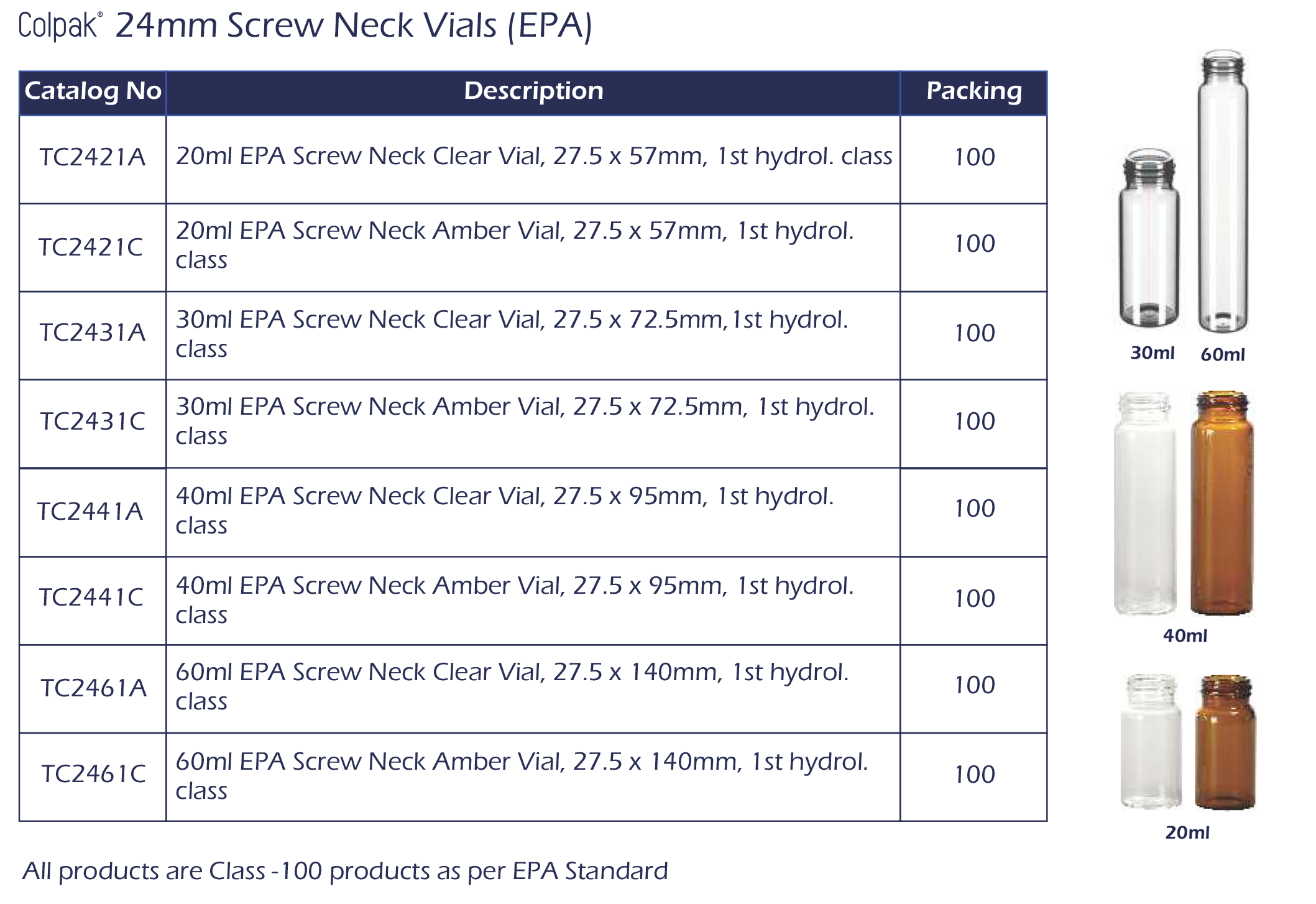

VOA / EPA Vials

Why Select Screw Neck Vials (EPA)?

Broad range of EPA Vials in clear and amber glass. Volume of 20ml, 30ml, 40ml and 60ml available. All types of EPA vials can be delivered against a small surcharge with a certificate of cleanliness that might especially be needed for TOC analysis. EPA Vials can be obtained with any type of screw seal ND 24.

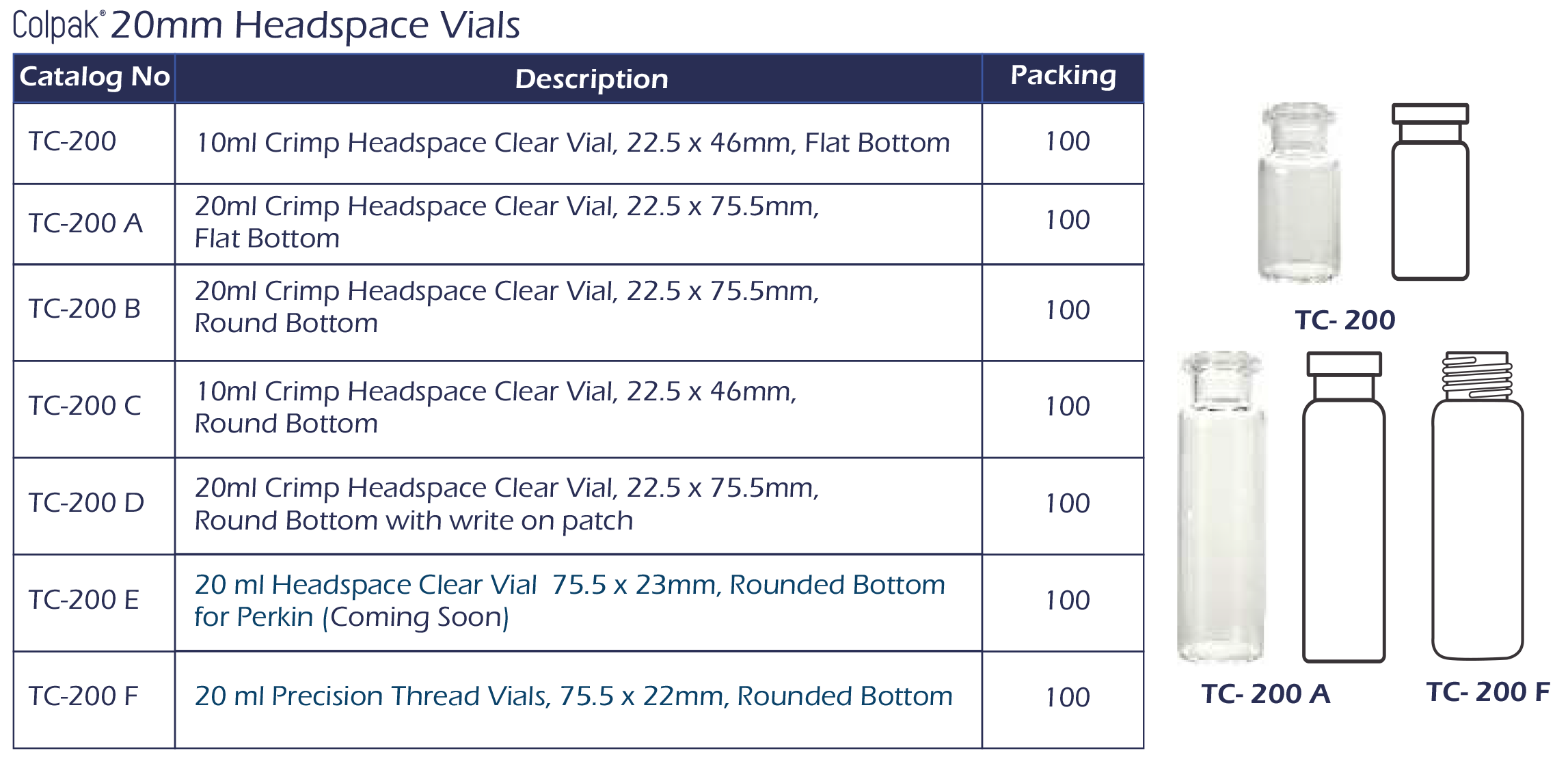

Headspace Vials

Why Select Headspace Vials?

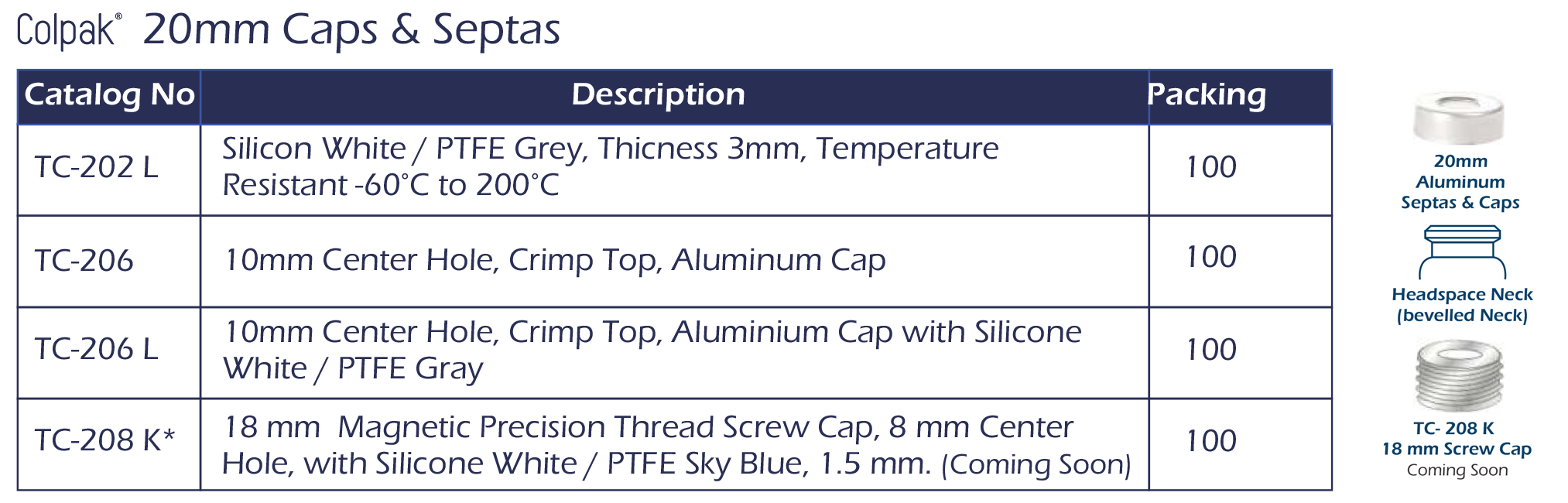

Colpak high quality headspace vials have a bevelled neck for a secure seal, uniform glass thickness for even heat distribution and a stable, strong design for ease of use. They are available with rounded or flat bottom profiles for accurate instrument compatibility. Use with the 20mm headspace caps, septas and seals. All vials are manufacture with USP type 1 glass.

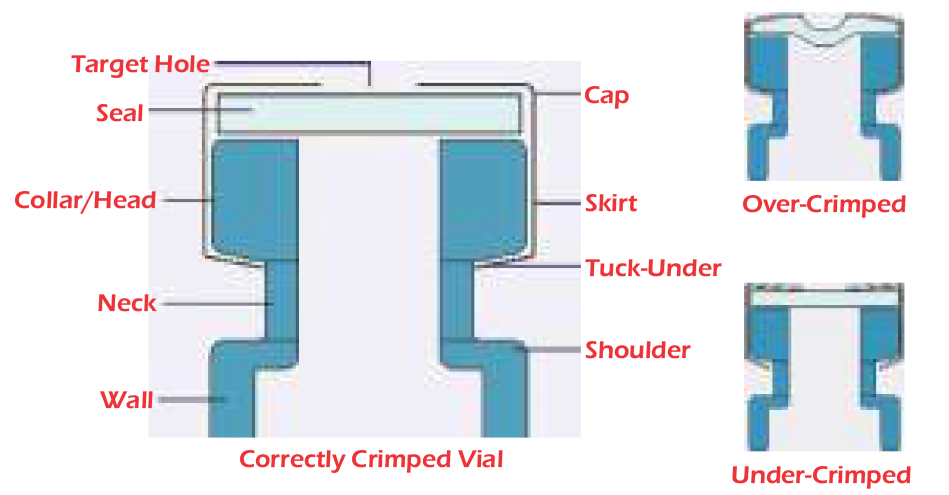

Over-crimping may cause coring or poor septum resealing, while under- crimping can cause evaporation problems.

With proper adjustment of the vial crimpers, Perfect crimping can be achieved every time. When the vial is crimped perfectly, the cap should not be able to rotate and the septum should appear smooth and level.

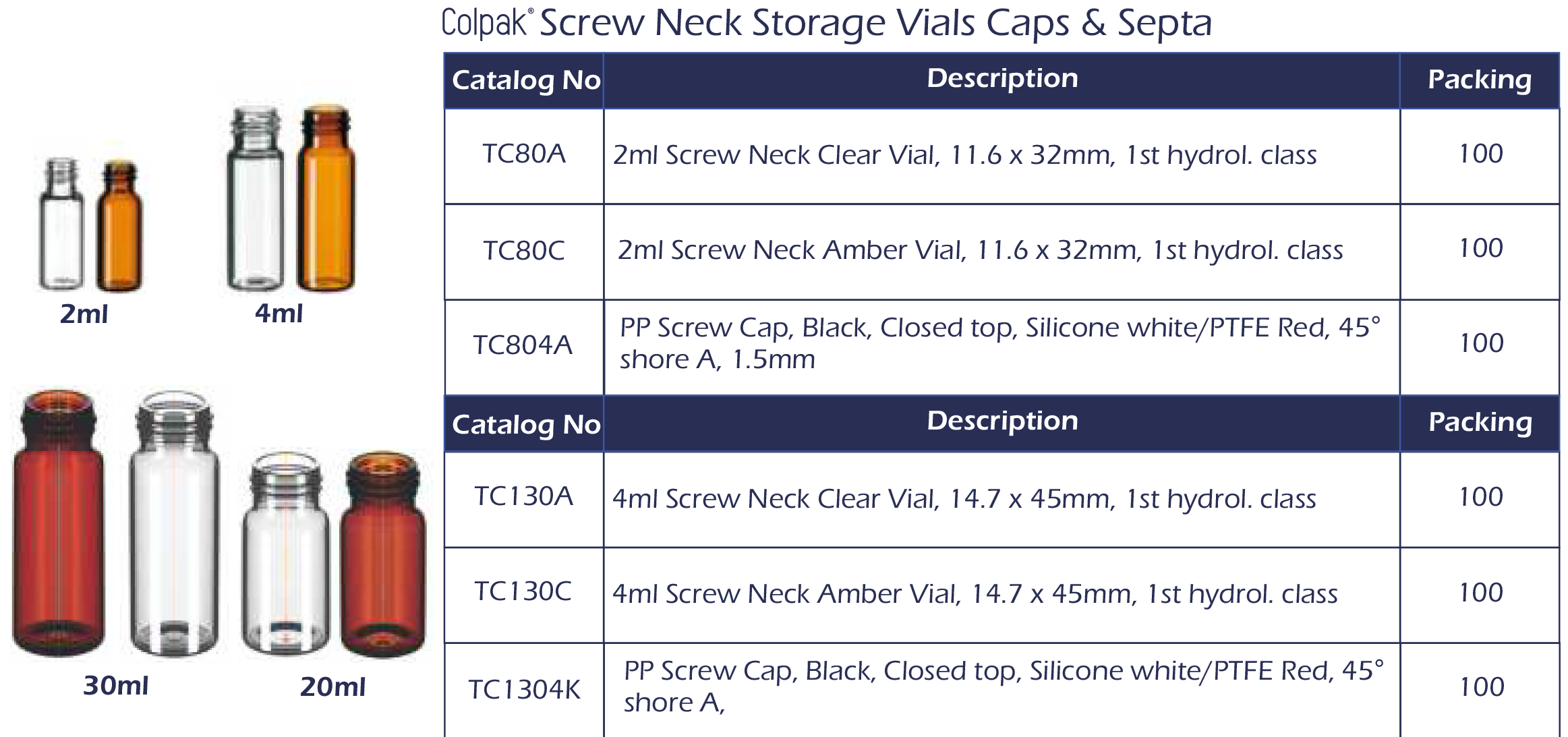

Storage Vials

Why Select Screw Neck Vials for Storage Purpose?

Screw Neck Vials for Storage Purpose made out of 1st hydrol. class glass. Vials with different volumes are available. Clear amber glass Vials. Seals with different septa

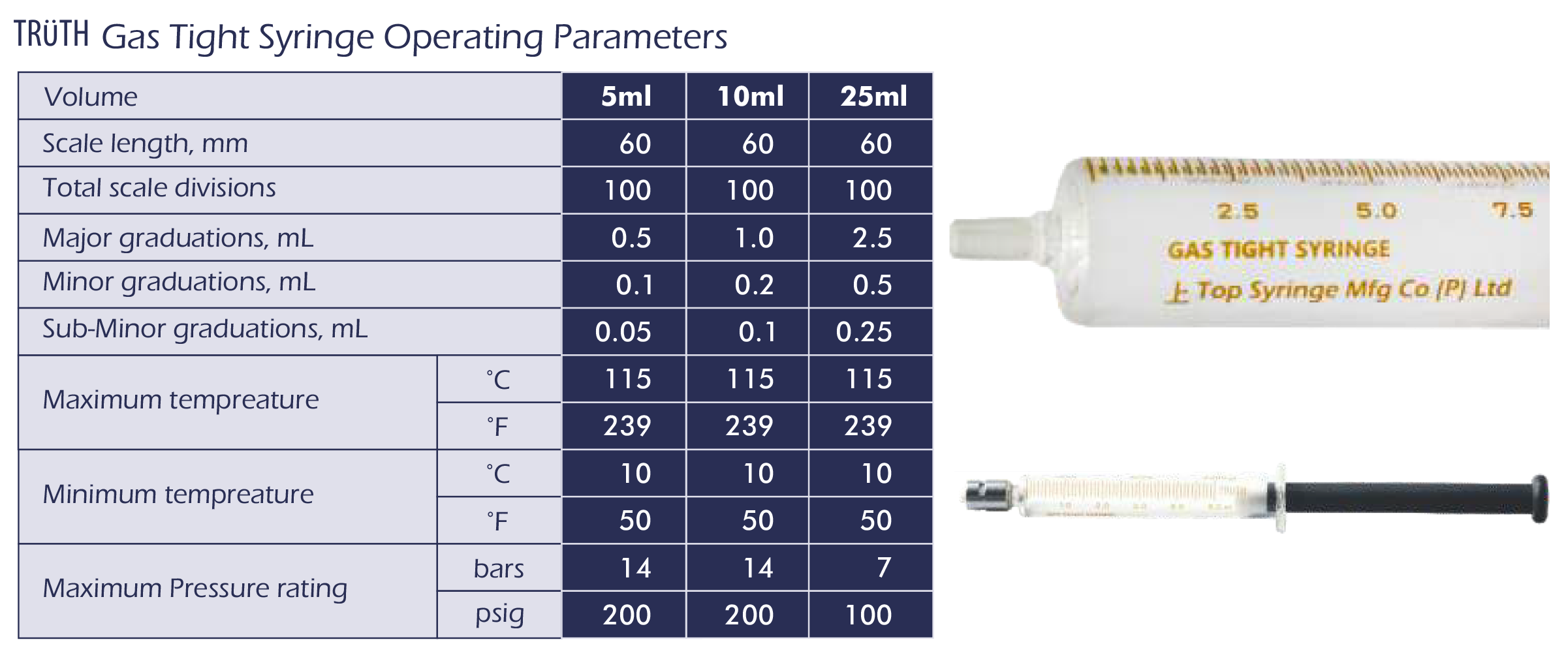

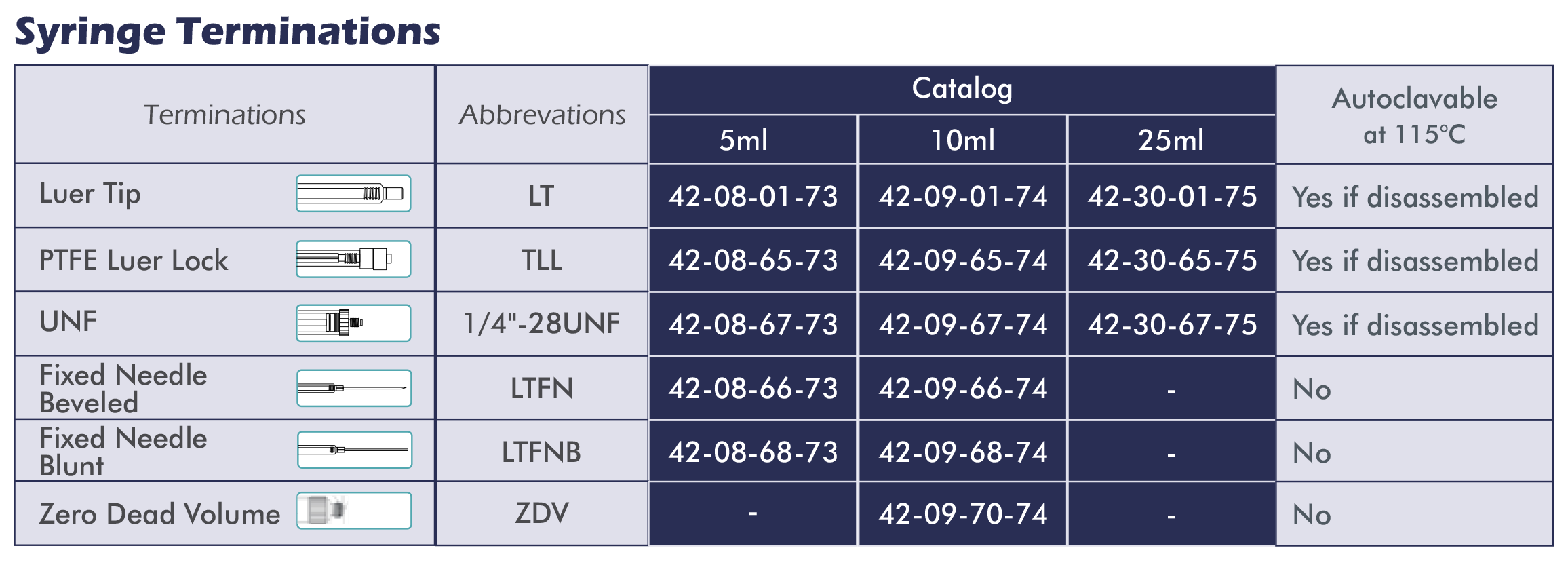

Gas Tight Syringes

Gas Tight syringes are ideal for dispensing both liquids and gases. They have a precision-machined PTFE plunger tip which creates a leak-free seal. With the tight fit, the tip essentially wipes the interior of the syringe barrel free of sample. This feature is particularly useful with heterogeneous samples as it reduces the chance that a deposit will occur and cause the plunger to freeze.

Zero Dead Volume:

The 6cm V6 syringe is designed and manufactured under stringent manufacturing and quality standards. These precision syringes are commonly used in clinical and analytical instrumentation where precision dispensing is critical. The syringes are able to handle your critical applications

Physical

- Length :4.37"

- End Cap: ¼-28

- Plunger Button: XL style Optimal Internal Pressure 80 PSI

Environmental

- Storage Temperature : 10°F to 180°F °C

- Operating Temperature : 50°F to 104°F

- Humidity : up to 100%

Chemical

- Wetted Materials: Borosilicate Glass, Kel-F (CTFE), Teflon (PTFE), UHMW (optional tip material), Lubricated with Medical grade lubricant

Performance

- Cycle life: PTFE Tip= up to 400K full stroke cycles* UHMW Tip = up to 800k full stroke cycles*

Accuracy/Precision

- 1% at 10% of total volume (with Di Water)

Technical Specifications

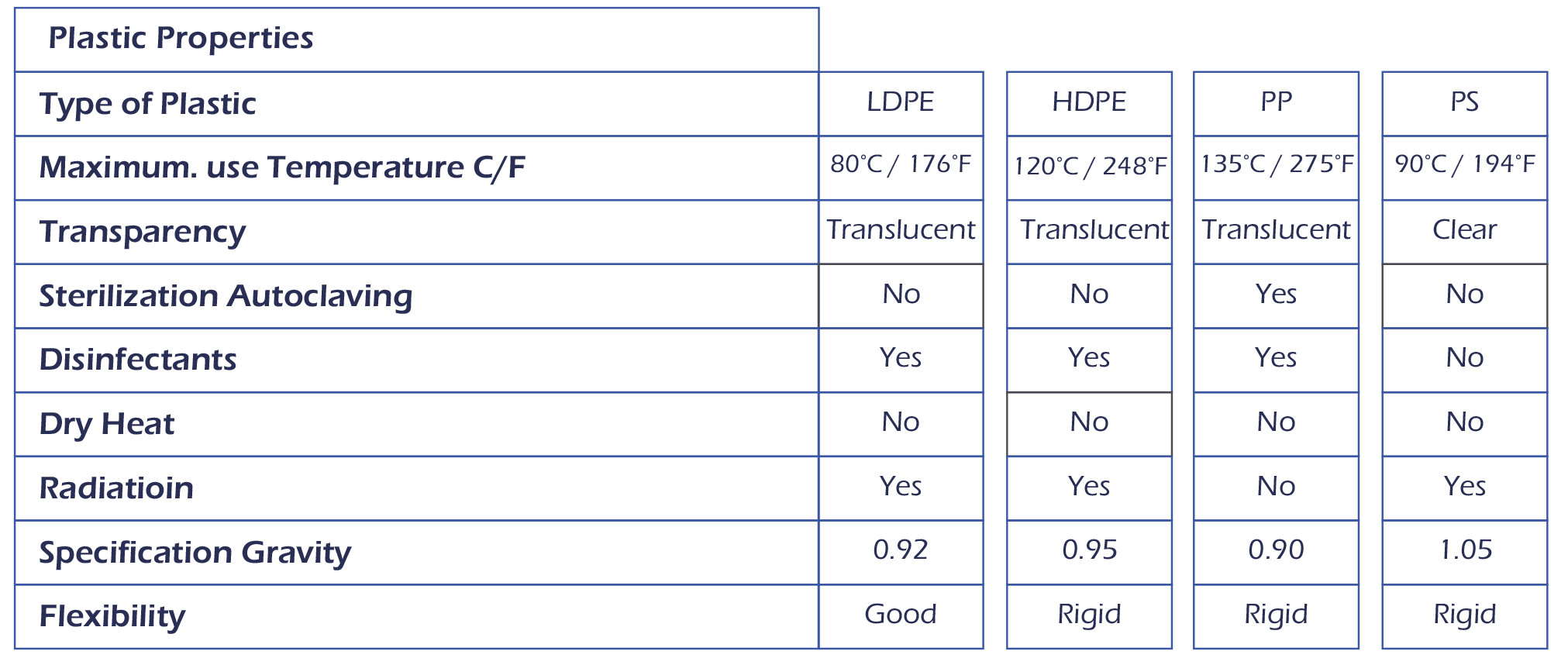

Factors for Selecting a Glass Container Chemical Durability

The U.S. Pharmacopeia classifies pharmaceutical glass containers according to their chemical durability, which is their resistance to water attack. Different types of glass react differently when exposed to solutions and vapors. Reactive substances will leach constituents from the glass surface into the contained product. This reaction can occur with ordinary aqueous, saline and alcohol based solutions. The primary ion removed from the glass surface is sodium; however all elements are subject to leaching. It is not uncommon to experience an increase in product pH as sodium is extracted from the container. Corrosion of the glass occurs over time and is accelerated by moist heat-treating processes like autoclaving.

Containers are classified by the USP as Type l, Type II and Type lll. Type I is the most chemically durable glass and Type III is the least durable. Test methods and specification limits are determined by the USP in Chapter <660> Containers. USP Type can be used as a general guide for container selection but should not be the only criteria in the decision making process. A set of criteria has been developed over the years to assist with the selection of glass containers. These guidelines were established to narrow the selection of possible containers. It is the product manufacturers responsibility to do testing to ensure that the glass container is suitable for the application and contained product.

USP Type I

USP Type I classification is a borosilicate glass with superior chemical resistance. This class of glass represents the least reactive glass containers available. Typically, this glass can be used for most applications, including packaging for parenteral and non-parenteral products. Type I glass may be used to pack acidic, neutral and alkaline products. Water for injection, unbuffered products, chemicals, sensitive lab samples and those requiring sterilization are commonly pack in Type I borosilicate glass. Type I glass can be subject to chemical attack under certain conditions, thus container selection must be made carefully for very low and very high pH applications. Most glass laboratory apparatus are Type I borosilicate glass.

Even though Type I glass has the highest chemical durability, there still may be some sensitivity with certain pack products. For applications where standard Type I glass does not provide sufficient protection against alkali extraction and pH shifting, internal surface treatment can be used to further improve the chemical durability of the container. This surface enhancement may become especially important for pH sensitive products pack in small containers because smaller containers have a higher surface area to volume ratio. See the USP Type II description for an explanation of the internal surface treatment process. It should be noted that the USP does not place any additional durability requirements on surface treated Type I glass.

USP Type II

USP Type II glass is soda-lime glass that has been treated with sulfur compounds to de-alkalize the interior surface of the container. This treatment results in a container with high chemical resistance because alkali is removed from the glass surface prior to use. The amount of ions available to leach into the product is reduced, thus the container durability is increased. Extraction salts will be present on the interior surface of new sulfur treated containers, and the containers may require washing prior to use. Type II glass is less chemically durable than Type I glass, but is more chemically durable than Type III glass. It can be used for acidic and neutral parenteral preparations that remain below pH 7 during their shelf life.

Factors other than USP Type

Handling Considerations:

Handling Considerations:

The physical design of the container will play a part in the amount of thermal and mechanical shock resistance it exhibits. It is often necessary to make a compromise between high resistance to mechanical shock and high resistance to thermal shock.

Light Sensitivity:

Light sensitive products must be packaged in amber glass. Amber glass is formulated to absorb light in the Ultra Violet region of the electromagnetic spectrum. Test methods and specification limits for light protection can be found in the U. S. Pharmacopoeia.

Specific Ion Sensitivity:

If a product is sensitive to the presence of particular ions, the composition of the glass container should be considered. For example, products that contain sulfate salts may experience the formation of precipitates if packaged in glass with barium or calcium in the formulation. In this example, it would be desirable to avoid glass that contains barium and calcium. A second example is pre-cleaned containers for environmental sampling. Even though the containers are clean, the chemical durability characteristics of the glass have not been altered. Thus, it would not be feasible to test the samples for low levels of sodium, because the sample will extract sodium from the container's surface.

Glass Manufacturing Terminology

Annealing Point

The temperature at which internal stresses in glass are significantly reduced. In the annealing operation, glass is gradually cooled from above the annealing point temperature to below the strain point temperature. This slow cooling relieves residual thermal stresses that would develop if the glass were allowed to cool in an uncontrolled manner.

Borosilicate Glass:

A high silicate glass that has at least 5% boron oxide.

Contraction Coefficient:

The fractional change in length of a piece of glass per degree change in temperature on cooling from the annealing point to ambient temperature.

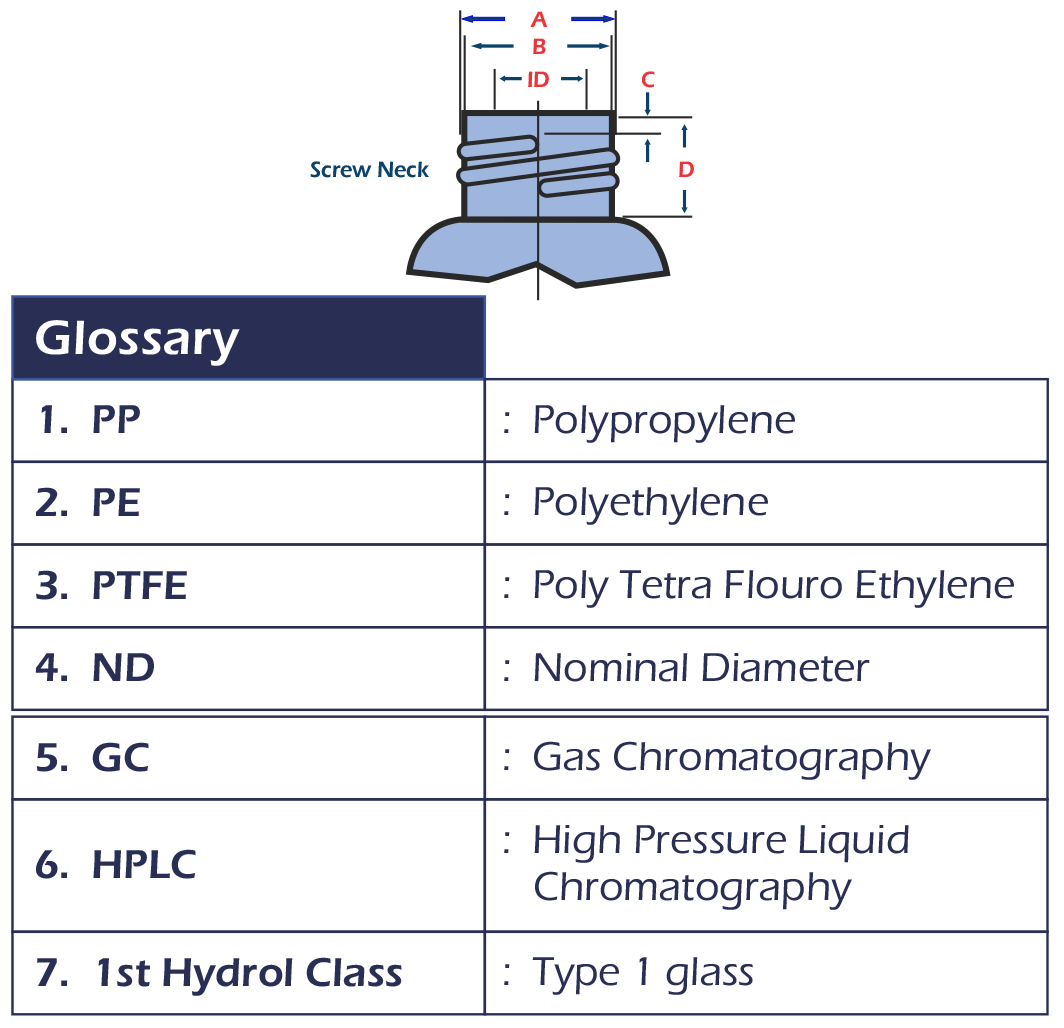

Finish:

The part of a bottle which holds the stopper or closure. The area that has the threads (generally a shortened term for thread finish). The first part made on an automatic machine, but the last part (or finish) to be made when bottles were hand blown. On labware, may refer to an interchangeable ground joint.

Forming: The shaping of hot glass.

Hard Glass: A glass with a high softening point or high viscosity (usually borosilicate).

Lehr: A long belt-fed, tunnel-shaped oven used to heat glass to the annealing point and then slowly cool it to room temperature to remove any residual thermal stresses in the glass. Can also be a large oven where glass is manually loaded and unloaded (batch lehr).

Linear Coefficient of Expansion:The fractional change in length of a piece of glass per degree change in temperature. The coefficient of expansion generally indicates the thermal endurance of the glass. Glasses with a low linear coefficient of expansion can be subjected to greater rapid temperature changes with less chance of fracture than glasses with a high coefficient of expansion. (Generally, Type I glass has a lower COE than Type III).

Soda-Lime (or Soft) Glass: A glass with a substantial portion of lime in the formula.

Softening Point: Temperature at which a thread or rod of glass rapidly deforms under its own weight.

Strain Point :The temperature at which thermal residual stresses become permanent upon cooling. Temperatures above the strain point will introduce permanent stresses that can cause or contribute to fracture. At temperatures below the strain point, the glass can be temporarily heated and cooled without introducing permanent stress. The strain point can be considered the maximum service temperature.

Temper: The degree of residual stress in annealed glass as measured using polarized light techniques.

Type 33 is clear borosilicate glass referred to as Type 1, Class A-33 Expansion

- This is the lowest coefficient of expansion

- Highly resistant to chemical attack

- Total arsenic and antimony oxides are less than 0.05%

- Free of the elements of the calcium, magnesium and zinc group of heavy metals

- Not available as amber glass

Type 51 or 70 is clear or amber borosilicate glass referred to as Type 1, Class B-51 Expansion

- Comparatively low coefficient of expansion

- All round good chemicalcompatibility

- Good resistance to heat shock

- Higher metal content

- All amber vials are made from Type 1, Class B-51 or 70 expansion glass

- Amber glass is to be used for a light sensitive samples; however,if left out in daylight for extended periods of time the amber coloring will fade and become less efficient

GPI refers to the "Glass Packaging Institute” The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers. For example, and 9-425 neck finish is approximately 9 mm in diameter across the outside of the threads. The 425 represents the finish (style of thread). Note: The 9 mm thread finish does not appear in the GPI finishes. It is not a standard finish.

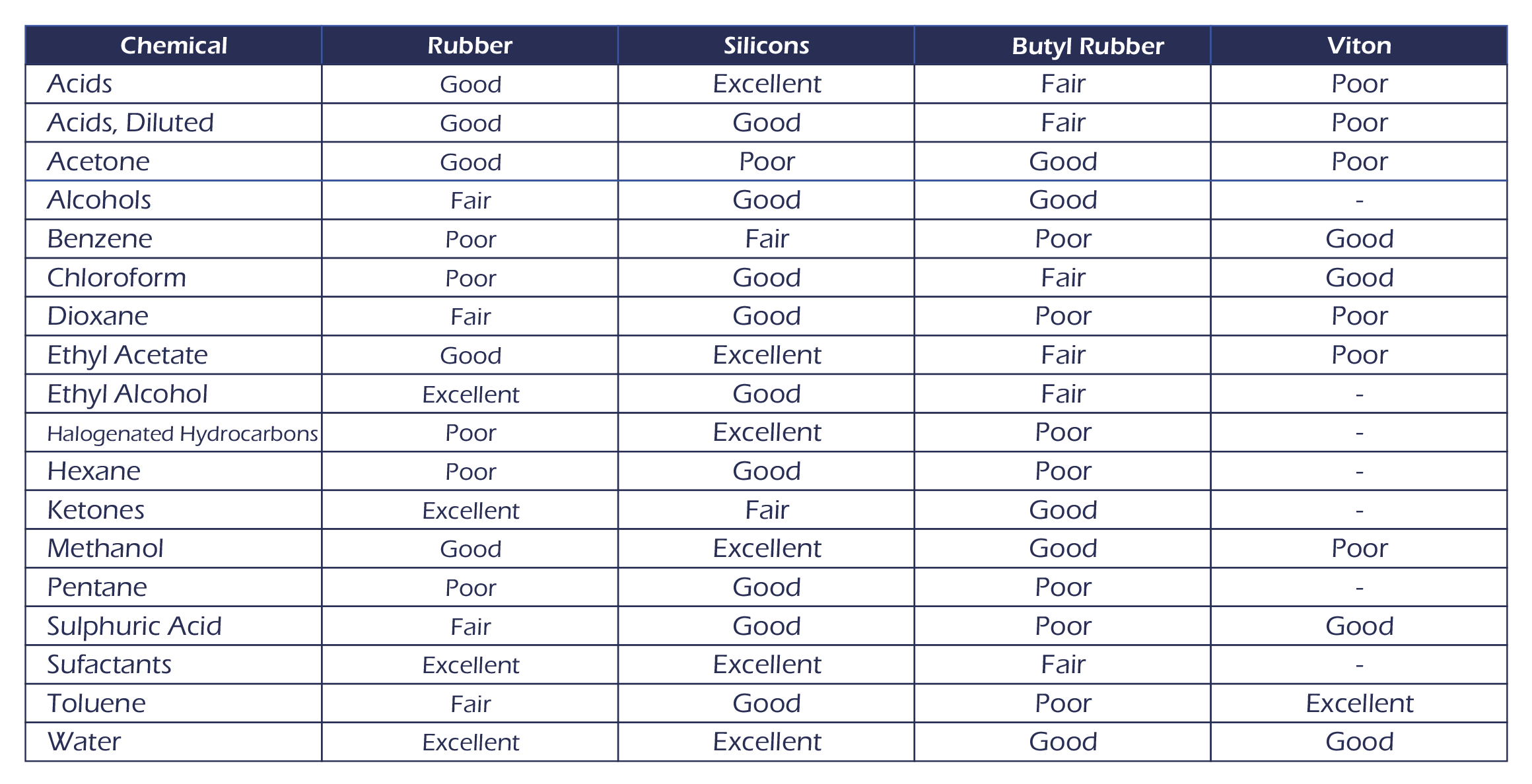

Selecting the correct SEPTA

The selection of correct septa depends on the application. Almost all septa are laminated on one side with PTFE, which has a high chemical resistance and forms an inert barrier between samples and carrier material of the septa. The carrier materials have different physical and chemical properties, such as temperature resistance, reseal-ability properties, cleanliness, hardness, thickness, etc.

The individual conditions of the user’s application aim at the specific characteristics of the carrier material, e.g.: Septa Compatibility Post Injection

Poor : Post injection this septa will exhibit sample loss and deterioration

Fair : Post injection this septa will maintain integrity for a limited period of time with some deterioration

Good : Post injection this septa will maintain integrity for an extended period of time minor deterioration

Excellent : Post injection this septa will maintain integrity for high percentage of analytical sample analysis with absolute minimal deterioration

PTFE

- Exceptional solvent resistance with superior chemical inertness

- Only suitable for single injection use – not recommended for sample storage before or after injection

- Not resealable

- The most economical septa

- Maximum service temperature 260°C

PTFE / Silicone

- Excellent resealing capabilities – highly recommended for multiple injections and sample storage

- Autoclavable and excellent resistance to coring

- PTFE chemical resistance until pierced then the septa will have the compatibility of silicone Temperature range -40°C to 200°C, For thin Fragile needle

Pre-Slit PTFE / Silicone

- Reduces the possibility of coring with blunt tipped needles or for applications using a thin gauge needle

- Used to prevent vacuum from forming inside the vial

- Temperature range -40°C to 200°C, For Blunt, thick needle

PTFE / Silicone / PTFE

- Recommended for multiple injections due to above average resealing capabilities

- Autoclavable and excellent resistance to coring

- Recommended for demanding applications such as internal standards, trace analysis or applications where there will be a long time between injections

- Temperature range -40°C to 200°C

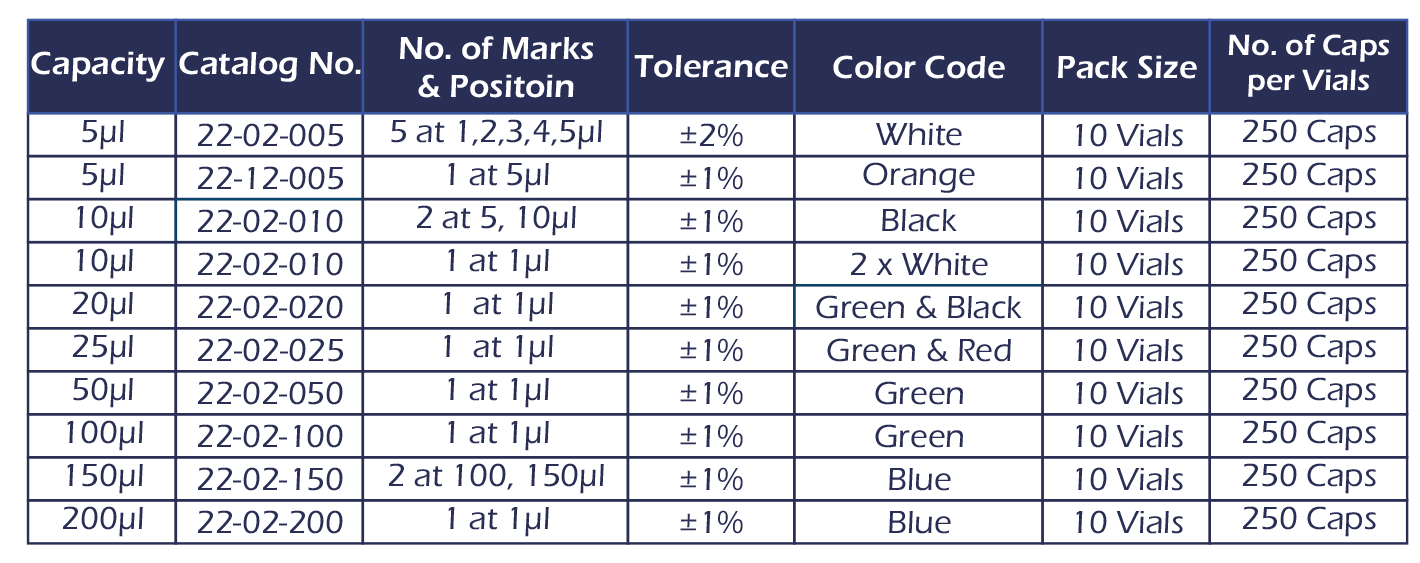

Glass Micro Capillaries Pipettes

MUCAPS are high precision capillary pipettes made of borosilicate netural glass with a precision bore, accurately cut and fire polished.

Graduated, GR Micro Capillaries

GR micro capillary pipettes are calibrated to contain specified volume when filled between end opposite to colour code band (indicating capacity) and black ring (indicating graduation).

Accessories: Bulb Dispenser

Precision - bore capillary tubes are calibrated to contain when from end to end. Insert a tube into the reusable dispensing bulb assembly and capillary action draws fluid up to the full capacity. Simply squeeze the bulb to dispense. Each case contain one bulb and 100 disposable tubes.

TempoHouse,1st Floor,

Top Syringe Compound, W. E. Highway,

Pandurang wadi, Mira Road (East),

Thane 401104.INDIA

Mob.: +91 9769175036

Email: sales@glass-syringe.com

Web: www.glass-syringe.com www.top-syringe.com

Marketed by

Tempo Instruments Pvt. Ltd.

Tempo House, Top Syringe Compound,W. E. Highway, Pandurang wadi,

Mira Road (East), Thane 401 104. INDIA

E-mail: tempo@vsnl.com

Website: www.tempo.net.in

10-11, Prospect Chamber Annexe, 317-21,

Dr. D.N. Road, Fort,Mumbai, 400 001. INDIA

Tele Fax. +91.22.2204.5352

Alovie Technologies

Plot#609, 1st floor, Pragathi Nagar,

Opp. to JNTUC, Kukatpally,

Hyderabad, Telangana.

Email: info@alovie.com

Website: http://www.alovie.com/